TOPIC :- HUMAN ERRORS

Understanding Human Errors.

Investigation of human errors.

Regulatory expectations.

CAPAs.

Current way of handling human errors.

Case study.

Human Error Is The Leading Cause Of GMP Deviations

25-60% of the deviations / Incidents in the companies are caused by Human errors

Human Errors-Regulatory Observations :-

Warning Letter / FDA 483

- Foreign matter was identified as a known process-related defect, yet no specific root cause for the particulate was identified. And the most likely root cause of failure to identify the critical/major defects during 100% visual inspection was identified as human error.

- High percentage rate of invalidated OOS (77%)test results without appropriate investigation was identified contributing mainly because of human error, instrument/column error, and method error.

- Multiple LI investigations lacked scientific rationale for root cause Probable root cause were attributed to contamination and analyst error

- CAPAs have often been limited to retraining Improvement in analytical methods and equipment were not generally implemented to enhance robustness and prevent error.

Current CAPAs

- Training / Re-training

- Display notification

- Take actions on the employee

- One point lesson

- Revise SOP

Human Error Classification Table

| Action Type | Subtype | Description | Error Type | Associated Gap |

|---|---|---|---|---|

| Unintended Action | Slip of Action | Error in execution (e.g., pressing wrong key) | Execution Error | Attention Gap |

| Lapse of Memory | Forgetting a step or detail | Memory Error | Attention Gap | |

| Rule-Based Mistake | Misapplying a known rule or SOP | Decision/Rule Error | Understanding Gap | |

| Knowledge-Based Mistake | Inadequate knowledge or misjudgment | Knowledge/Skill Error | Proficiency Gap | |

| Intended Action | Situational Behavior | Action taken under pressure or poor judgment | Situational Deviation | Behavioral Gap |

| Exceptional Behavior | Deliberate rule-breaking or non-compliance | Intentional Deviation | Behavioral Gap |

Important points for human error investigations

- Pre-defined Interview

- Photographic evidence

- Approved hypothesis plan (Wherever required)

- Spot verification (Gemba walks)

- Data analysis based on system, person, area, process, system etc

Summary

- Human errors do happen

- Categorize it as Human error after all possible causes have been

- Small quantity of deviations to result from human error

- Investigation should be thorough to ensure that cause is

- Eliminated any possible process, environment, procedural or system based issues.

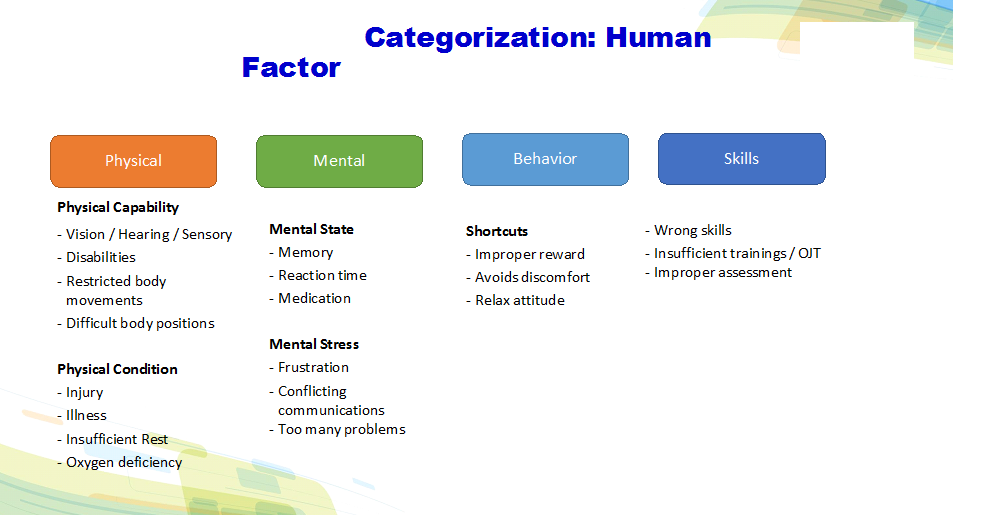

- Classify human errors in Attention gap, understanding gap, skill gap and behavioral gap.

- Take appropriate actions based on the causes

- Look for error proofing instead of blame, duplication etc.