Quality by Design (QbD)

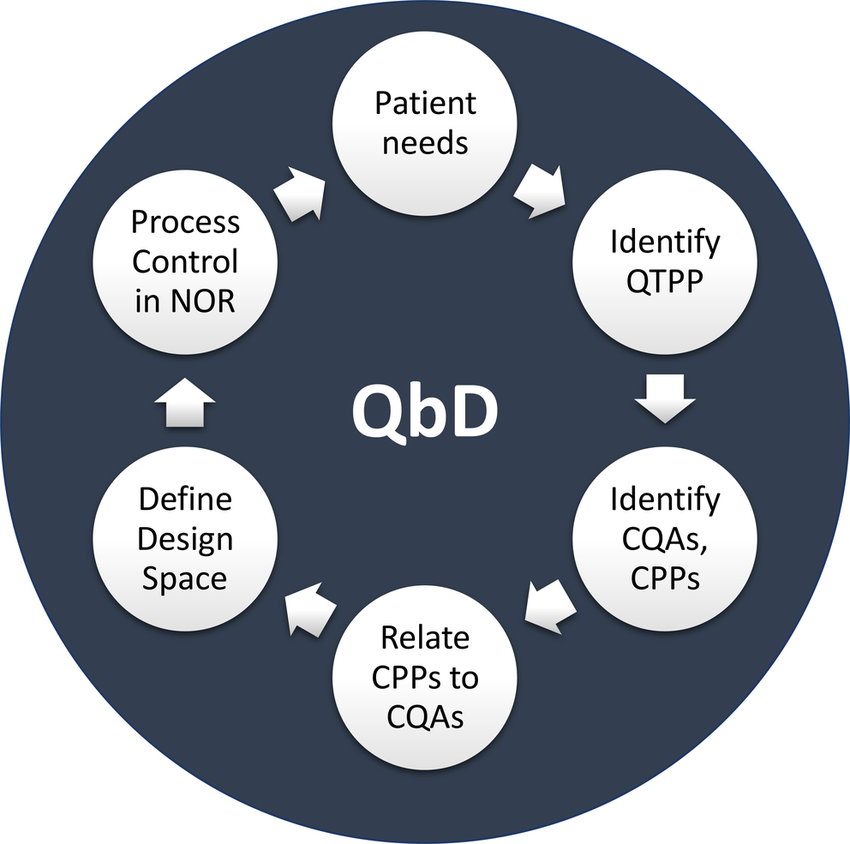

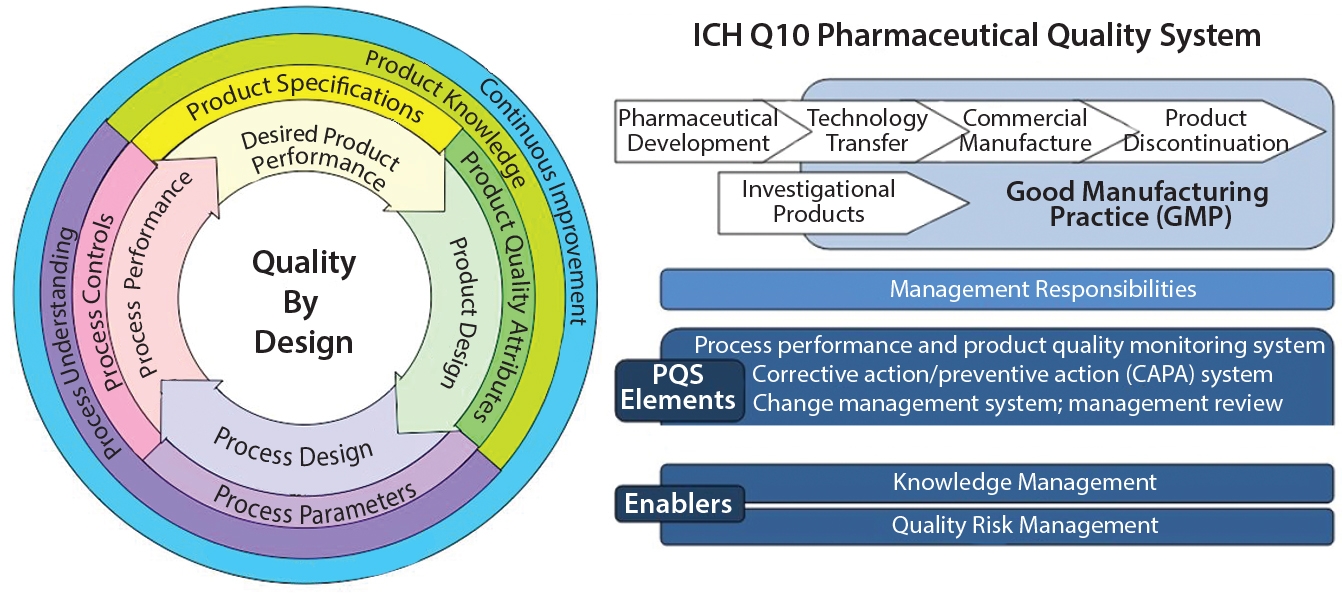

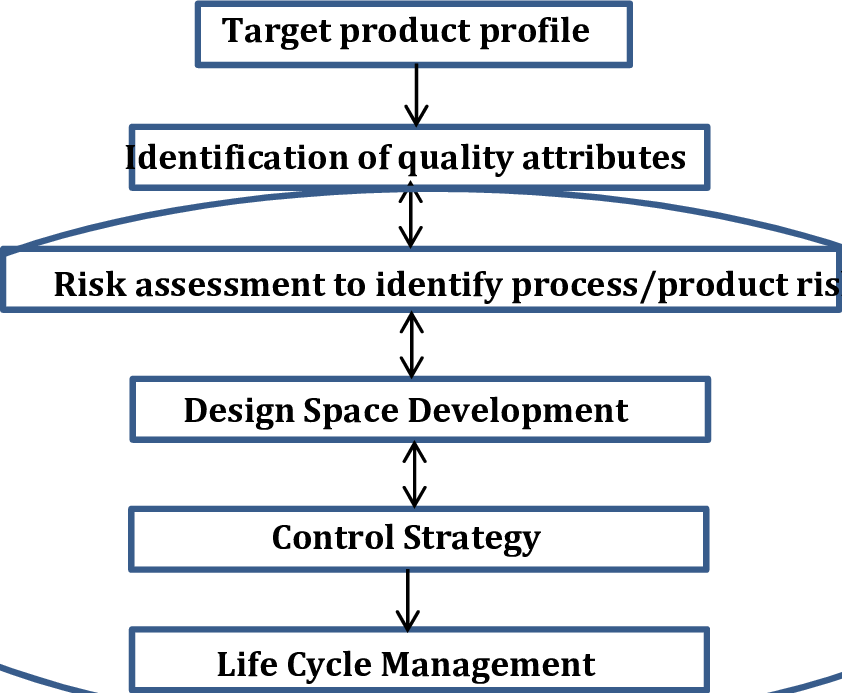

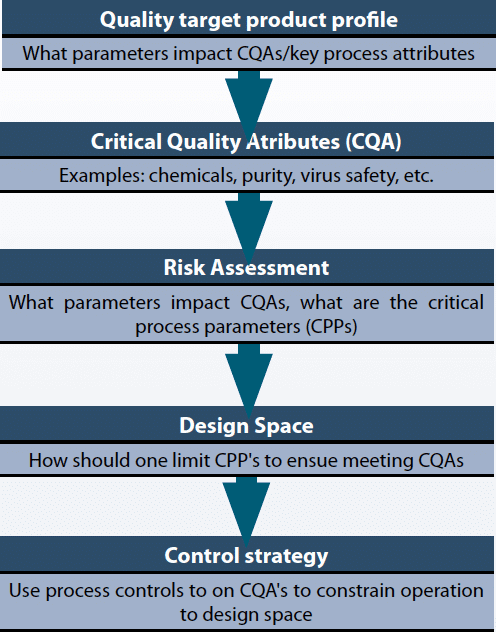

Quality by Design (QbD) is a systematic approach to product development that builds quality in from the start by focusing on a deep understanding of the product and its manufacturing process. It uses a science-based, risk-management approach to identify critical quality attributes (CQAs) and critical process parameters (CPPs), establishing a “design space” and control strategy to consistently meet quality targets throughout the product lifecycle.

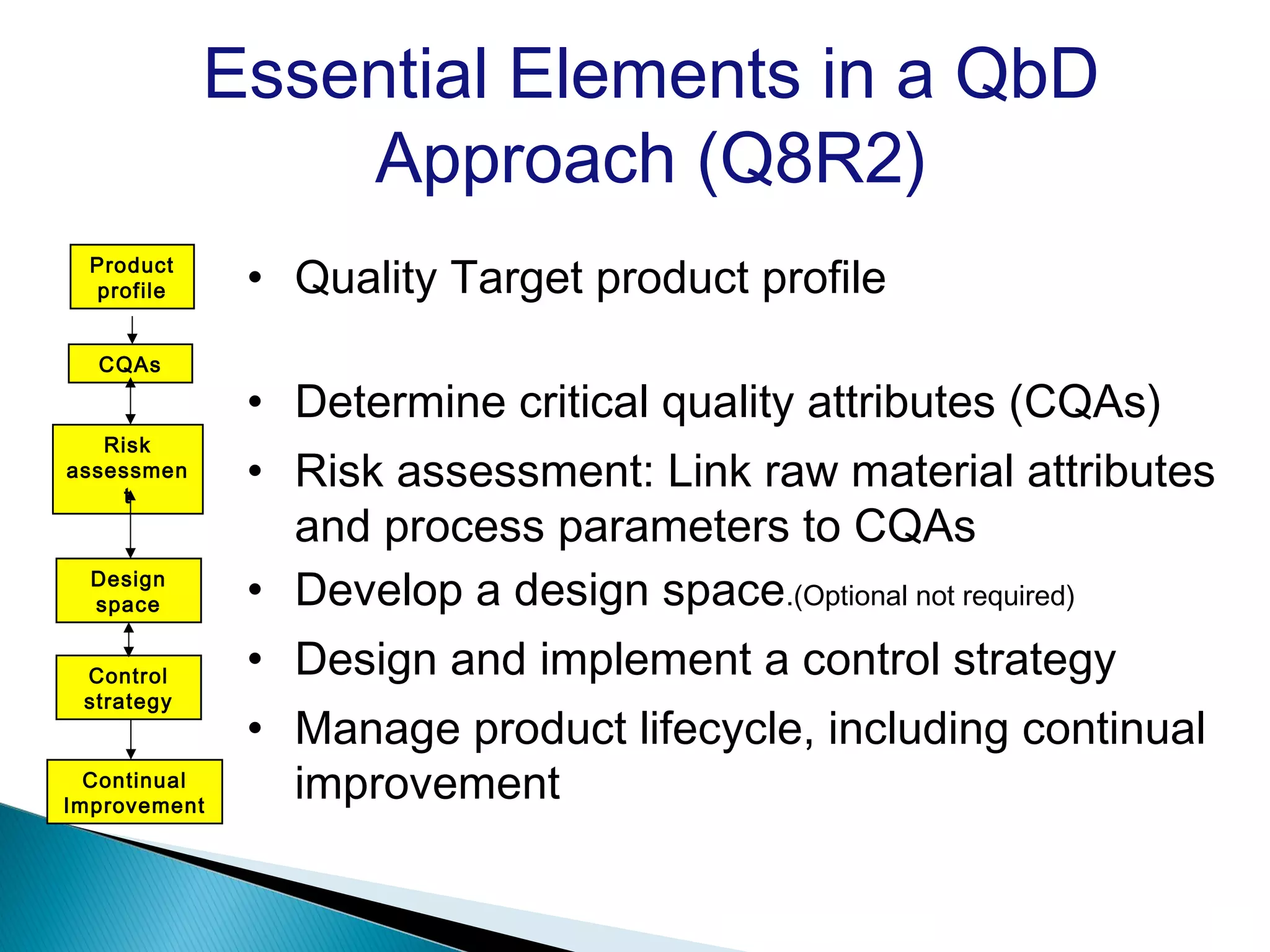

Key principles and steps :-

- Start with the end in mind:Define clear objectives and a Quality Target Product Profile (QTPP), which outlines the desired characteristics of the final product.

- Identify critical quality attributes (CQAs):Determine the measurable characteristics of the product that are essential for its performance and safety.

- Identify and understand critical process parameters (CPPs):Identify the variables in the manufacturing process that have the most significant impact on the CQAs. This is done through experimentation, risk assessment, and statistical analysis.

- Establish a design space:Define a multi-dimensional combination of input variables and process parameters that have been demonstrated to provide assurance of quality. This is the “safe operating zone” for manufacturing.

- Develop a control strategy:Implement a plan to manage the CPPs within the design space to ensure that the product consistently meets its quality attributes.

- Continuously improve:Use the understanding gained to support continuous improvement and innovation over the product’s lifecycle.