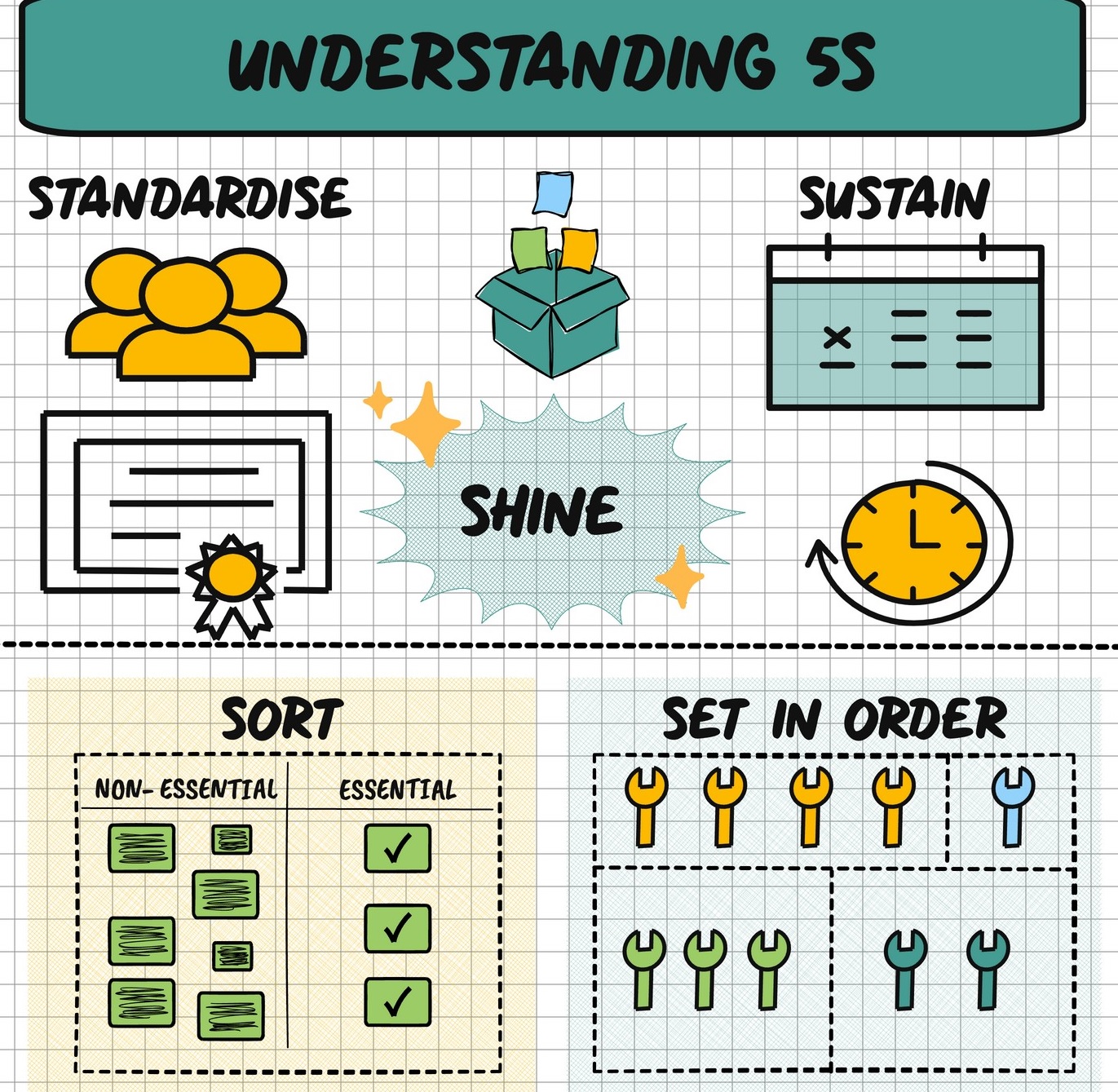

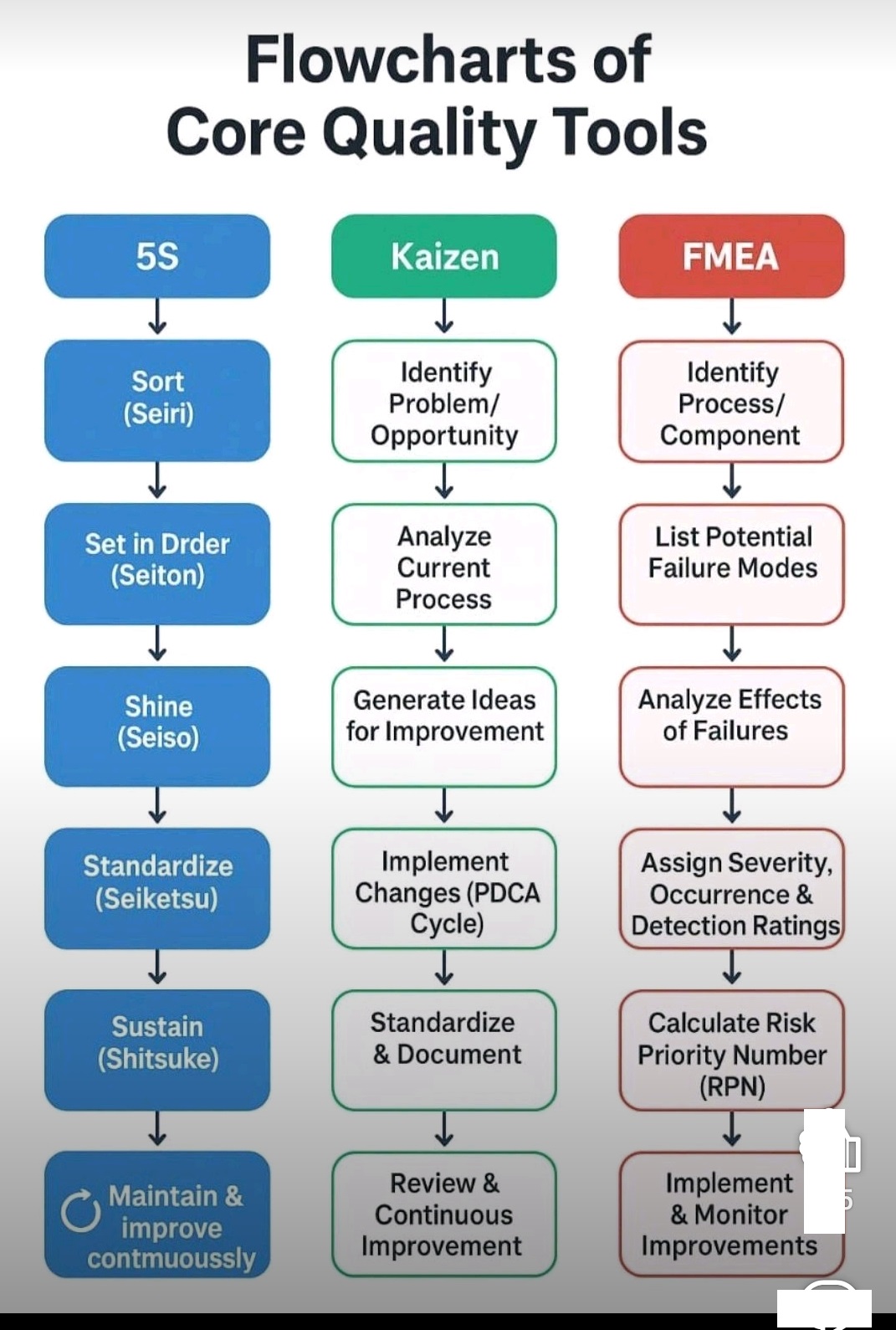

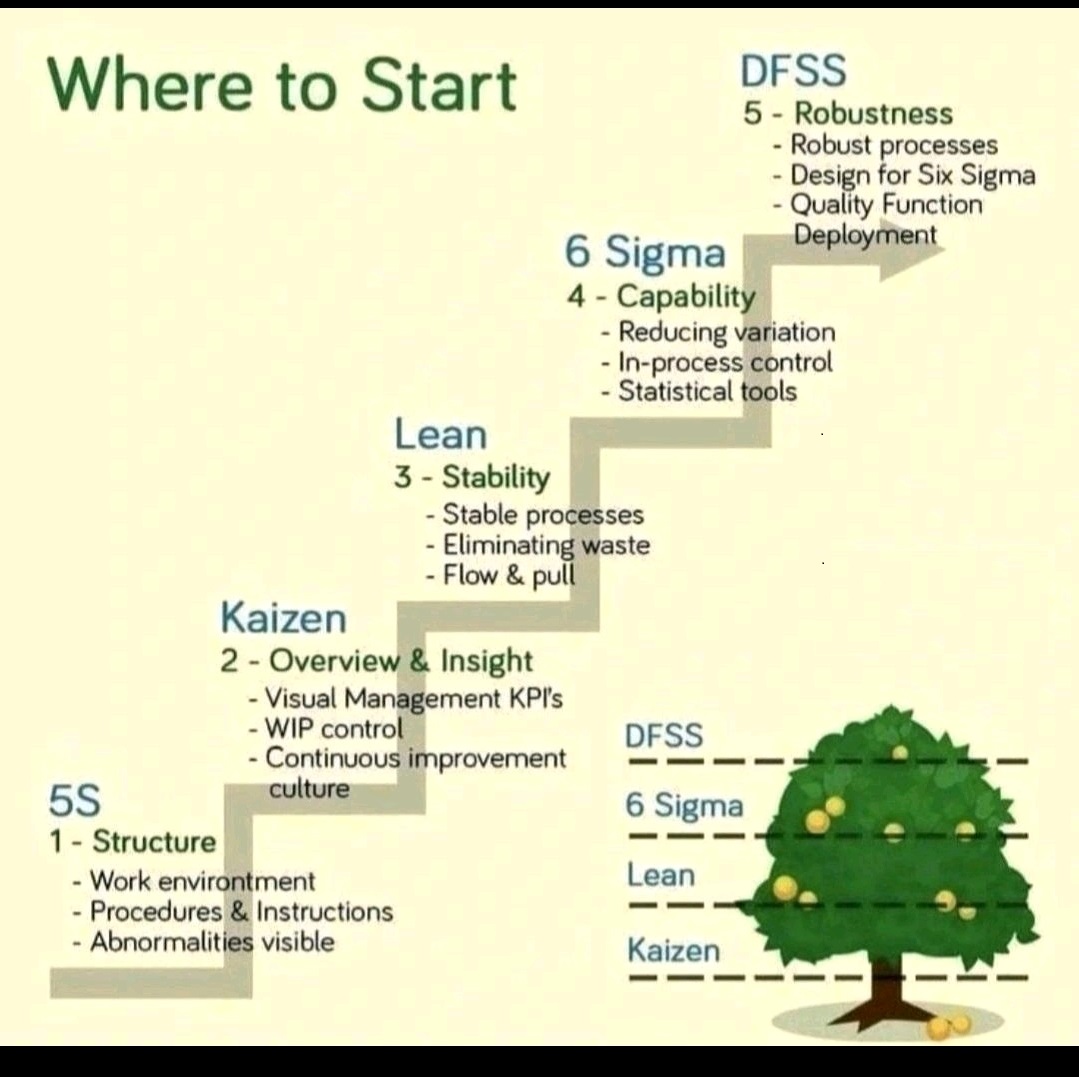

5S Technique

The 5S step is a Lean methodology for workplace organization, focusing on five Japanese words starting with ‘S’

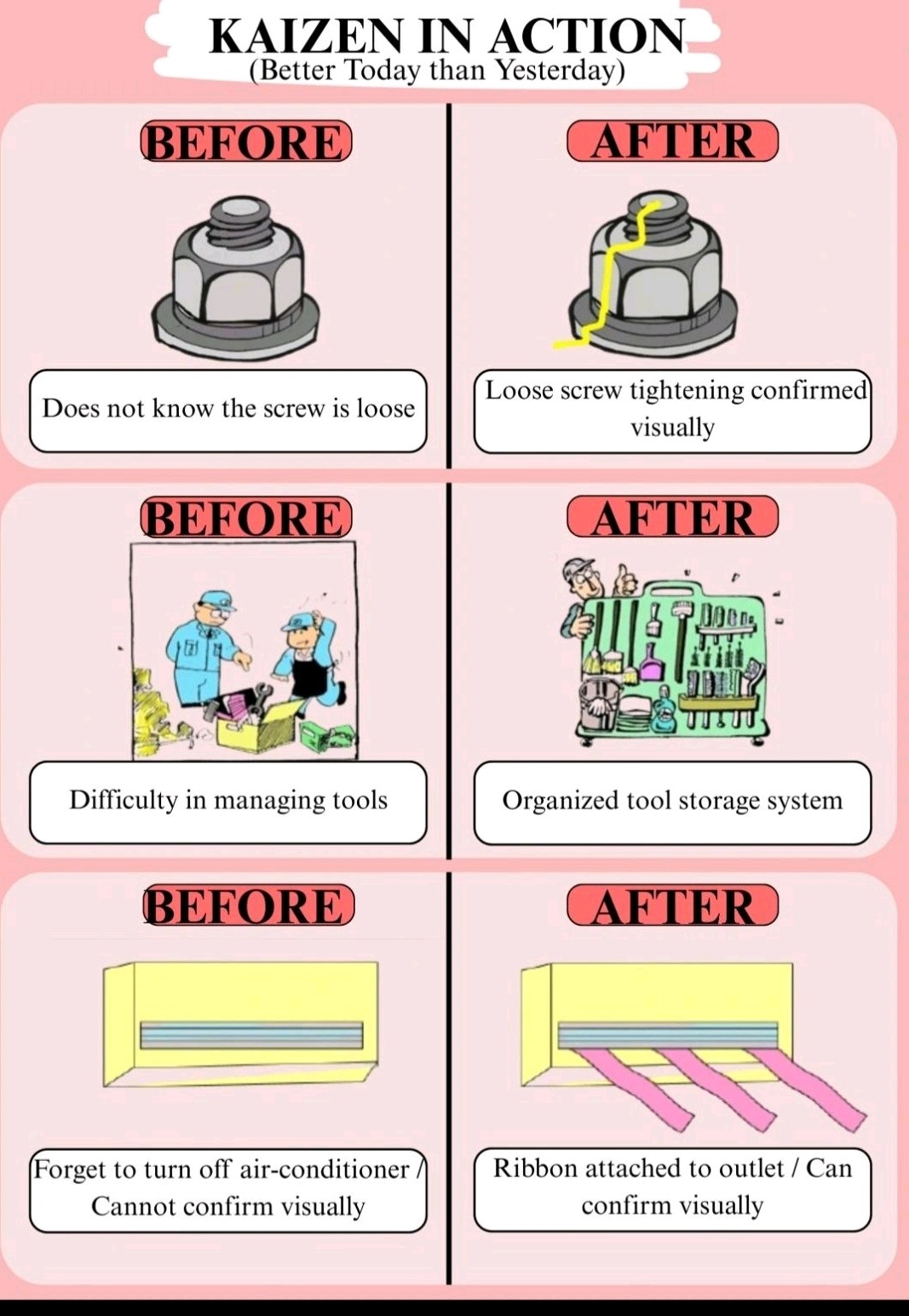

2. Set in Order (Seiton): Arrange necessary items so they are easy to find, use, and return, with a designated place for everything (e.g., “a place for everything, and everything in its place”).

3. Shine (Seiso): Clean the work area thoroughly and regularly, making cleaning part of the routine to prevent issues and maintain safety.

4. Standardize (Seiketsu): Create procedures, checklists, and schedules to ensure the first three Ss (Sort, Set in Order, Shine) are consistently followed.

5. Sustain (Shitsuke): Develop the discipline to maintain the standards over time through audits, training, and management commitment, turning 5S into a habit.

6M Process Control

6M Process Control