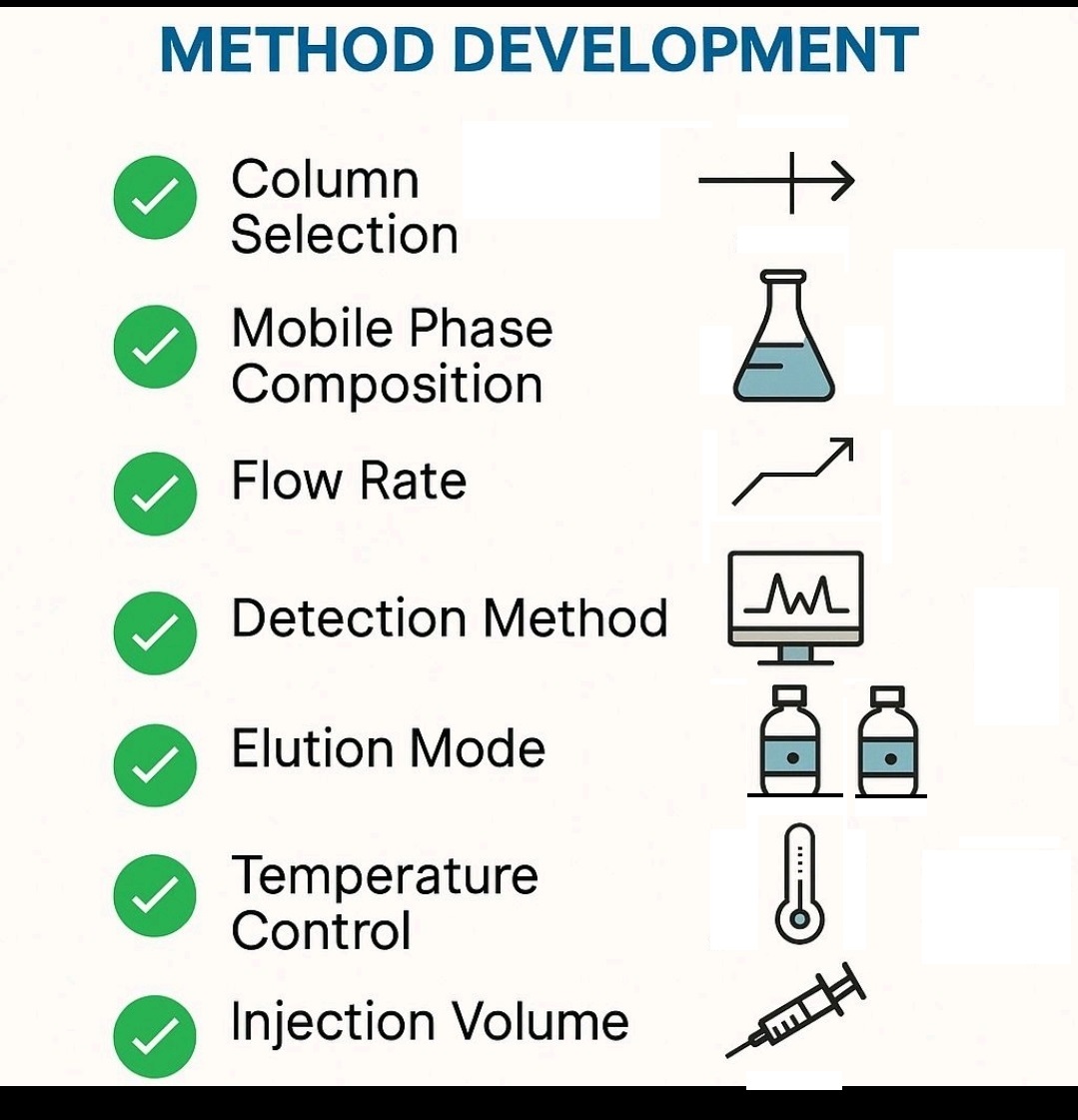

Ruggedness vs Robustness

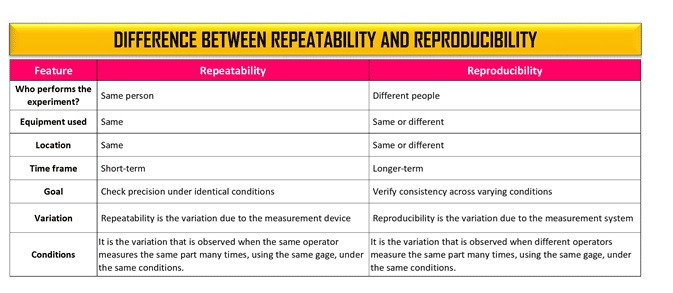

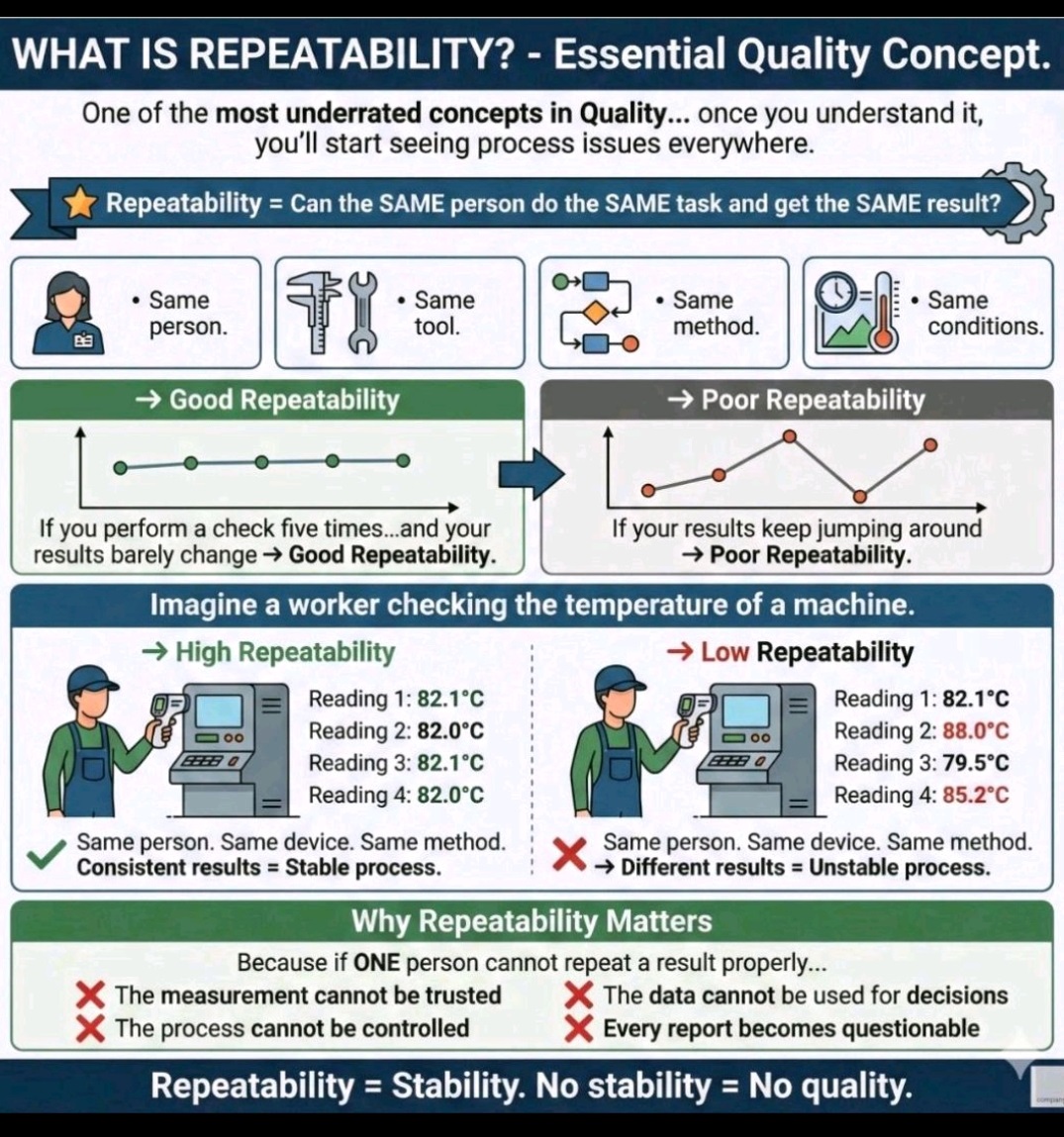

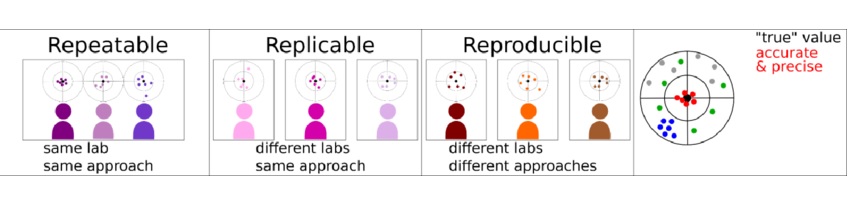

Ruggedness and robustness both measure an analytical method’s reliability under varying conditions, but robustness tests its stability against small, deliberate changes in its own parameters (like pH or flow rate) within one lab, while ruggedness assesses its consistency across different external factors (like analysts, instruments, or labs) for real-world reproducibility.